SZ CnAuto automation equipment Co., Ltd.

Specializing in the production of automatic\precision\high speed dispenser manufacturers

Hot Tel:

18929475867

Specializing in the production of automatic\precision\high speed dispenser manufacturers

Hot Tel:

18929475867

TEL:

18929475867

深圳中制自動化設備有限公司

Email:jerry@prcrobot.net

QQ:a :

ADD:東莞市塘廈鎮(zhèn)石潭浦大逕路62號

作者:吳交易???日期:2019-06-19 21:39???瀏覽:

In 2012, many manufacturers still use hot melt glue guns, heating and hot melt glue dispensing, dispensing accuracy is difficult to control, can only rely on the feeling and the naked eye to control the amount of glue, in the perfume bottle dispensing and tablet computer border dispensing can not be carried out, the production speed is really too slow, after the dispenser manufacturers strive to develop and develop hot melt adhesive machine accessories, that is, the temperature heating device and hot melt glue point. Rubber valves, hot melt glue dispensing valves store hot melt particles, and the temperature heating device to the dispensing valve temperature heating, temperature control in the glue melting point, and then use automatic hot melt glue dispensing machine.

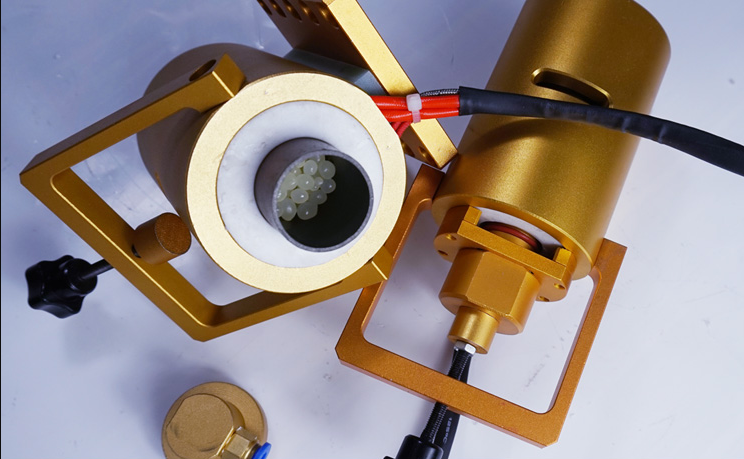

In 2012, many manufacturers still use hot melt glue guns, heating and hot melt glue dispensing, dispensing accuracy is difficult to control, can only rely on the feeling and the naked eye to control the amount of glue, in the perfume bottle dispensing and tablet computer border dispensing can not be carried out, the production speed is really too slow, after the dispenser manufacturers strive to develop and develop hot melt adhesive machine accessories, that is, the temperature heating device and hot melt glue point. Rubber valves, hot melt glue dispensing valves store hot melt particles, and the temperature heating device to the dispensing valve temperature heating, temperature control in the glue melting point, and then use automatic hot melt glue dispensing machine. The highest temperature of the temperature heating device can reach 225 degrees high temperature. The hot melt adhesive can be completely fused. Besides the temperature heating, there is another characteristic that can control the air pressure. The automatic hot melt glue machine needs air pressure, so the temperature heating device is able to heat the glue and control the air pressure, while the hot melt glue dispensing valve controls the flow and the accuracy. Frame dispensing needs the combination of hot melt glue machine accessories to meet the dispensing requirements.

The highest temperature of the temperature heating device can reach 225 degrees high temperature. The hot melt adhesive can be completely fused. Besides the temperature heating, there is another characteristic that can control the air pressure. The automatic hot melt glue machine needs air pressure, so the temperature heating device is able to heat the glue and control the air pressure, while the hot melt glue dispensing valve controls the flow and the accuracy. Frame dispensing needs the combination of hot melt glue machine accessories to meet the dispensing requirements.

After various introductions and application analysis, we have a certain understanding of the parts of hot melt glue dispensing machine. We also know what kind of dispensing equipment is needed for hot melt glue dispensing. Automatic hot melt glue dispensing machine is one of the types of dispensing machine, and its structure is not too complicated. As long as the temperature heating device and hot melt dispensing valve are installed on the automatic dispensing machine, it becomes an automatic hot melt. Glue dispensing machine, and then change the dispensing machine program, the internal procedures and machines to cooperate, you can dispensing.

After various introductions and application analysis, we have a certain understanding of the parts of hot melt glue dispensing machine. We also know what kind of dispensing equipment is needed for hot melt glue dispensing. Automatic hot melt glue dispensing machine is one of the types of dispensing machine, and its structure is not too complicated. As long as the temperature heating device and hot melt dispensing valve are installed on the automatic dispensing machine, it becomes an automatic hot melt. Glue dispensing machine, and then change the dispensing machine program, the internal procedures and machines to cooperate, you can dispensing.