Fully automatic hot melt dispensing machine with hot melt di

作者:吳交易???日期:2019-06-10 11:26???瀏覽:

Guide: Hot melt dispensing valve is a very special type of dispensing valve. It can only use one kind of glue, which is hot melt glue, other glue will not use this dispensing valve. Although only one kind of hot melt glue can be used, it is very popular in the market. A hot melt dispensing valve price is about 15, that is, dispensing valve with constant temperature system device.

Component of Automatic Hot Melt Adhesive Machine

The automatic hot melt adhesive machine is made up of general automatic dispensing machine + hot melt glue dispensing valve + constant temperature system device. After the combination, hot melt adhesive can be used for dispensing, and the dispensing of perfume bottle and the border of the tablet computer can use this hot melt glue dispenser. The effect of glue production and production speed are greatly improved. The main point is that the accuracy of dispensing can be controlled within the range of requirements. At present, except for hot melt glue dispensing machine, manual heating rubber gun can only be used, but the accuracy does not match the dispensing requirements of perfume bottles and tablet computers. This is a very bad point.

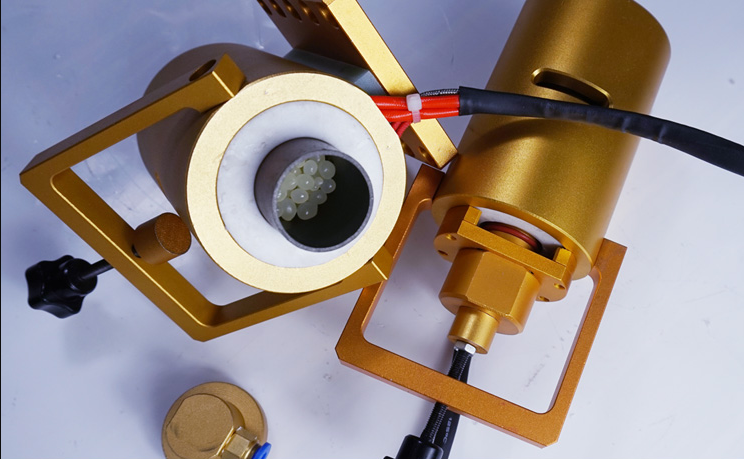

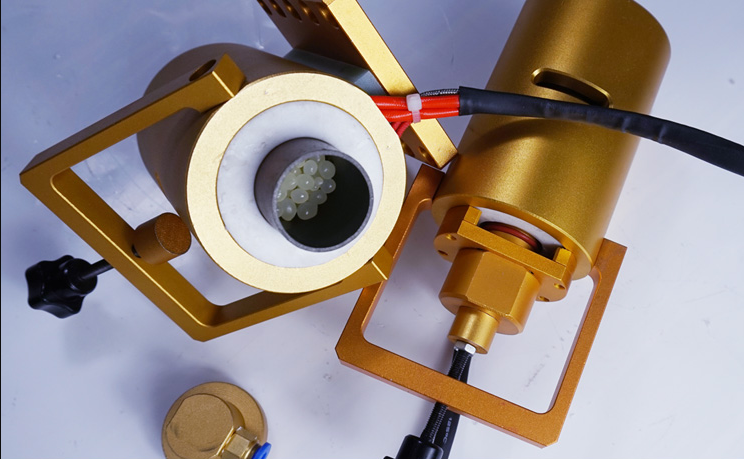

Components of hot melt dispensing valve

Hot melt adhesive dispensing valve is composed of aluminium alloy and high temperature resistant material. It can store hot melt rubber particles in 30cc dispensing syringe internally. After placing rubber particles, it can use thermostatic system to raise the temperature of hot melt adhesive dispensing valve. After waiting for the rubber particles to melt completely, it can use automatic hot melt machine to dispensing. Why can the thermostatic system control hot melt rubber dispensing? At a certain temperature, such as the melting temperature of hot melt glue is 100 degrees, the hot melt glue dispensing valve can be kept at this temperature.

Turn-on time of a hot melt dispenser

With hot melt dispensing valve and constant temperature system, it is easier to use hot melt glue. How long does it take to make a fully automatic hot melt dispensing machine that meets the requirements? The delivery time is about ten days. From receiving orders to testing products to delivering machines, it takes less time. This is also the speed that automatic dispensing machine manufacturers can achieve. For example, in the perfume bottle dispensing, we need to make a fixture that fits the perfume bottle cap. It also takes a little time to manufacture, and a variety of automatic dispensing machine debugging and so on. There are also system changes and so on, so the ten day delivery time is just reasonable.

It will be quicker to apply in tablet frame dispensing, because we already have mature dispensing technology, and the demand for automatic hot melt glue dispensing machine is not high, so we can deliver the machine within five days, but the process may change the time of dispensing. Now that the time of dispensing is finished, let's talk about hot melt dispensing valve and constant temperature system.

Time required to heat glue at 100 degrees

The maximum heating temperature of hot melt glue dispensing valve can reach 250 degrees. It only takes 3 minutes to heat to Baidu. The constant temperature system can set the temperature and pressure values to ensure the pressure value required by hot melt glue dispensing valve. Whatever industry it is applied in, it can meet its production needs. It is particularly convenient. The production technology of the whole automatic hot melt glue machine has matured and can accomplish each of them well. Requirements for dispensing in different industries.

If you want to know the requirements for dispensing bottles of perfume bottles and tablet dispensers, or want to know more about hot melt glue dispensing valves and automatic dispensing machines, you are welcome to call our telephone hotline: 13928403389.

The automatic hot melt adhesive machine is made up of general automatic dispensing machine + hot melt glue dispensing valve + constant temperature system device. After the combination, hot melt adhesive can be used for dispensing, and the dispensing of perfume bottle and the border of the tablet computer can use this hot melt glue dispenser. The effect of glue production and production speed are greatly improved. The main point is that the accuracy of dispensing can be controlled within the range of requirements. At present, except for hot melt glue dispensing machine, manual heating rubber gun can only be used, but the accuracy does not match the dispensing requirements of perfume bottles and tablet computers. This is a very bad point.

The automatic hot melt adhesive machine is made up of general automatic dispensing machine + hot melt glue dispensing valve + constant temperature system device. After the combination, hot melt adhesive can be used for dispensing, and the dispensing of perfume bottle and the border of the tablet computer can use this hot melt glue dispenser. The effect of glue production and production speed are greatly improved. The main point is that the accuracy of dispensing can be controlled within the range of requirements. At present, except for hot melt glue dispensing machine, manual heating rubber gun can only be used, but the accuracy does not match the dispensing requirements of perfume bottles and tablet computers. This is a very bad point. It will be quicker to apply in tablet frame dispensing, because we already have mature dispensing technology, and the demand for automatic hot melt glue dispensing machine is not high, so we can deliver the machine within five days, but the process may change the time of dispensing. Now that the time of dispensing is finished, let's talk about hot melt dispensing valve and constant temperature system.

It will be quicker to apply in tablet frame dispensing, because we already have mature dispensing technology, and the demand for automatic hot melt glue dispensing machine is not high, so we can deliver the machine within five days, but the process may change the time of dispensing. Now that the time of dispensing is finished, let's talk about hot melt dispensing valve and constant temperature system.

If you want to know the requirements for dispensing bottles of perfume bottles and tablet dispensers, or want to know more about hot melt glue dispensing valves and automatic dispensing machines, you are welcome to call our telephone hotline: 13928403389.

If you want to know the requirements for dispensing bottles of perfume bottles and tablet dispensers, or want to know more about hot melt glue dispensing valves and automatic dispensing machines, you are welcome to call our telephone hotline: 13928403389.