The case of automatic dispensing machine applying glue on PC

作者:涂膠機???日期:2020-05-14 15:19???瀏覽:

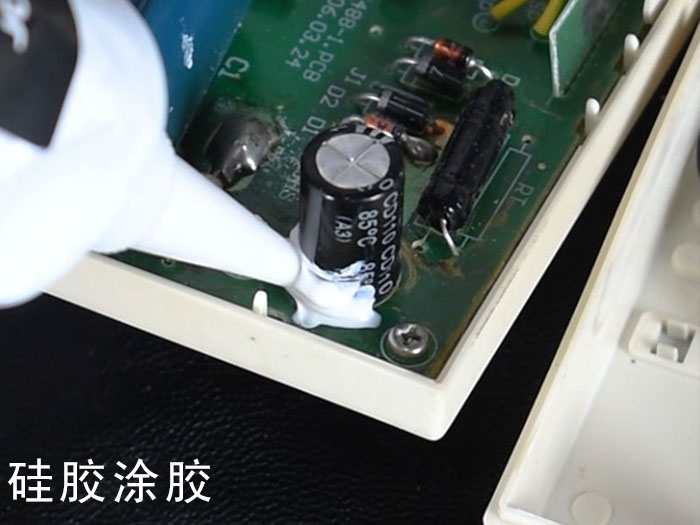

The gluing of printed circuit board is really one of the hot industries. There are too many gluing positions, which can be used for edge sealing, curing, gluing, etc. many products can be glued. Unless the manufacturer wants to reduce the production of products, the manufacturers with high quality requirements will basically match with the dispensing effect, because the gluing can play a waterproof effect, so it has a higher advantage to use with glue �����。

Now the volume of electronic industry is getting smaller and smaller. To fundamentally solve the dispensing problem, the requirements of dispensing machine are also improved, especially in terms of accuracy, it is possible to have a precision of 0.01mm, and some need to meet the special requirements of glue, such as heating, low temperature, high viscosity, etc. the technical requirements of gluing on PCB are still quite high. According to the actual situation, product estimation has become Normally, the general standard full-automatic dispensing machine refers to the machine specification, rather than dispensing configuration, and the price will fluctuate.

Production process

Determine product type → glue shape and parameters → dispensing accuracy requirements → determine production speed → plan to use machine type → match dispensing system → test product dispensing effect → determine machine and production mode.

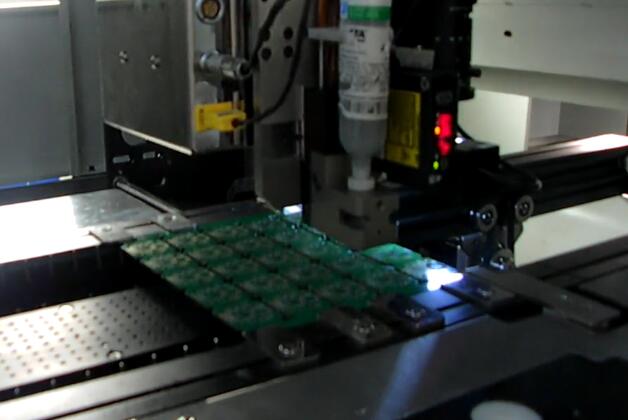

Printing circuit board gluing is our main application industry. At present, there are three kinds of automatic dispensers that meet the gluing demand. The price is divided into high, medium and low. The lowest configuration is table type three-axis automatic dispenser, spray type dispenser, and high-end visual dispenser. The price difference is quite large. The appropriate dispenser can be selected according to the production level.

Advantages of automatic dispensing machine

The advantage of using the full-automatic dispensing machine lies in the dispensing control, which fundamentally solves the two problems of speed and dispensing accuracy. Previously, it was basically produced by hand, and the speed is very slow. A work station needs about three to four people, but now only one machine is needed to meet the requirements of printing and brushing the circuit board, and also to realize the modern process production standard.

1. The dispensing stability is strong, and the glue quantity control is stable.

2. Automatic production effect, manual placement of products, automatic dispensing machine, fast efficiency.

3. Reduce production intensity, improve quality and product.

?��。?It has a long service life. A machine can be used for four or five years. There is no problem at all