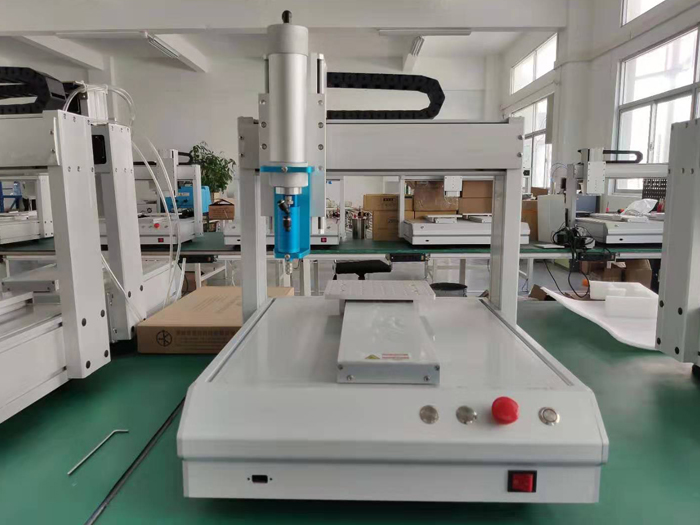

Electric iron handle applicator

作者:涂膠機???日期:2020-05-13 14:24???瀏覽:

Our company has a series of machines for gluing in the electric iron industry. As for the soleplate or screw, we have special machines, accessories matching and performance, the effect will be particularly obvious, which can solve a series of production problems, gluing accuracy, glue quantity control, production speed and quality assurance, with product quality assurance and obvious effect. It is more suitable for the handle of electric iron than general machines Application requirements.

The handle of the electric iron is pressed out by the mold. There is a specific model. Install the electrical components in the empty slot, and then cover the cover. This cover is the place where glue is applied. There are not many positions where glue is needed. Just apply a layer of glue, and then cover the cover. There is no need to screw, and the sealing is very strong. It can also avoid the external water entering the internal of the electric iron.

The cost of the glue applicator is very low, the price is about thirteen thousand, the cost is low, the service life is very long, it can reach three to four years, the glue applicator is stable, the precision is high, the glue quantity can be controlled, the quality is guaranteed, the production speed of the machine is certainly faster than that of the manual, the quality will be better, and the glue overflow problem can be avoided.

The glue application technology of electric iron handle is simple, the common type of glue applicator can meet the needs, with a set of reasonable machines, the application effect will be particularly obvious, so as to avoid the production problems. Our company fundamentally solves the glue application problem, the production structure is simple, and needs a manual auxiliary production, placement and taking products, the manual production intensity will be reduced, and the structure will be more obvious It's also very difficult to understand how to do it.

The automatic glue applicator is a desktop machine with a small structure platform and two working stations. It can apply glue to two products at the same time. By using the time difference method, it can solve the production intensity problem of workers and the production speed problem. From the lowest price to the highest value, the effect is very powerful, and fundamentally solve the dispensing problem.