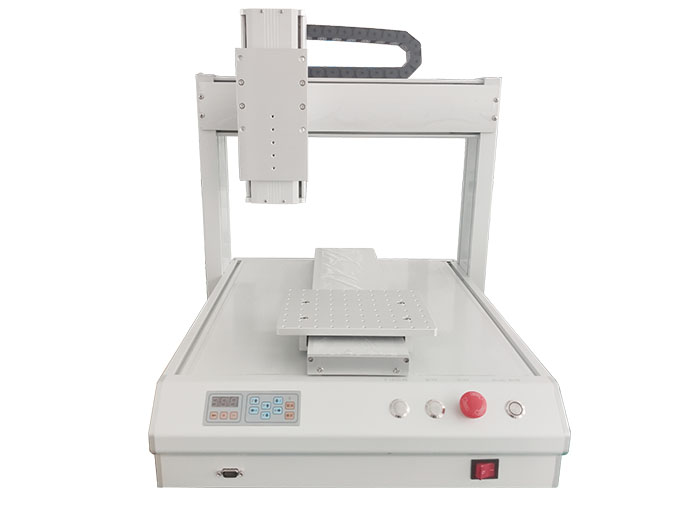

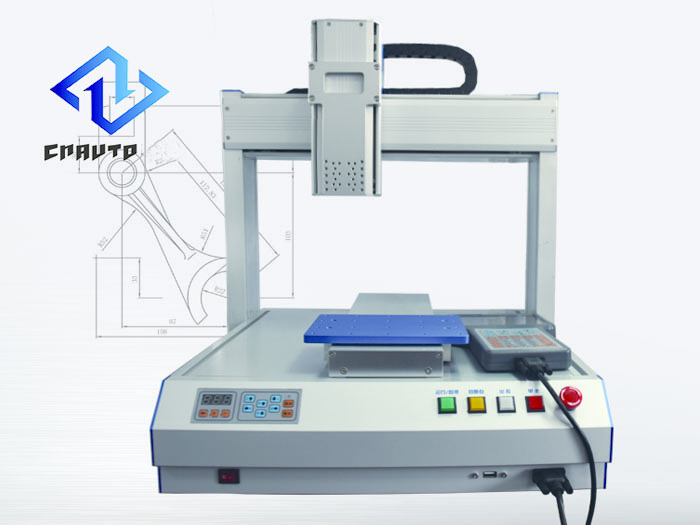

Three things to do in daily maintenance of glue coating mach

作者:馬交易???日期:2019-08-28 16:07???瀏覽:

The daily maintenance of glue coating machine directly affects its service life. Therefore, the daily maintenance of the glue coating machine can not only improve the quality of products, but also extend the service life of equipment, saving a lot of money for enterprises. Next, let's talk about how things are maintained on a daily basis.

Maintenance with different types of glue

As one of the routine maintenance of glue coating machine, it is necessary to clean pipelines and valves when replacing different kinds of glue. At this time, it is mainly to close the feed valve, open the discharge valve, discharge the residual glue in the stainless steel pressure barrel, close the discharge valve, open the feed valve, and pour the cleaning liquid into the pressure barrel, according to the conventional dispensing operation. Clean the glue inside the rubber valves, pipes and pressure barrels.

Use and Maintenance of Glue Pressure Barrel

Secondly, abnormal pressure and water vapor are found in the daily maintenance of glue coating machine. Please check the water vapor in the air pressure valve filter, or check whether the pressure source is abnormal. Before using dispensing machine, please use a small amount of products to test and display the operation, so that it can master the use of machine skills, so as to avoid breakdowns. When there is no problem in the experiment, it can use the dispensing machine to carry out large-scale production tasks.

Use and Maintenance of Two-Component Glue

Thirdly, when using two-component glue, we need to pay attention to the bubbles in glue. For example, when using epoxy resin glue to coat, we need to do the steps. Vacuum pump system uses vacuum to remove bubbles in the mixing process, or put 10-20 minutes before use to eliminate the bubbles in the mixing process. Bubble, guaranteeing that the bubbles in glue are discharged.

Secondly, abnormal pressure and water vapor are found in the daily maintenance of glue coating machine. Please check the water vapor in the air pressure valve filter, or check whether the pressure source is abnormal. Before using dispensing machine, please use a small amount of products to test and display the operation, so that it can master the use of machine skills, so as to avoid breakdowns. When there is no problem in the experiment, it can use the dispensing machine to carry out large-scale production tasks.

Secondly, abnormal pressure and water vapor are found in the daily maintenance of glue coating machine. Please check the water vapor in the air pressure valve filter, or check whether the pressure source is abnormal. Before using dispensing machine, please use a small amount of products to test and display the operation, so that it can master the use of machine skills, so as to avoid breakdowns. When there is no problem in the experiment, it can use the dispensing machine to carry out large-scale production tasks.