Key points for dripping of rubber valve in automatic dispens

作者:馬交易???日期:2017-11-10 11:57???瀏覽:

Automatic dispensing machine application range is very wide, but also on the chip in addition to other small objects outside the dispensing package for dispensing butt on some large objects, so very strong practical aspects of market sales volume is very considerable, the rubber valve is as important as the glue dispensing machine parts processing flow, parts selection to focus on rubber valve rubber valve, if the quality is not good when there may be all kinds of problems.

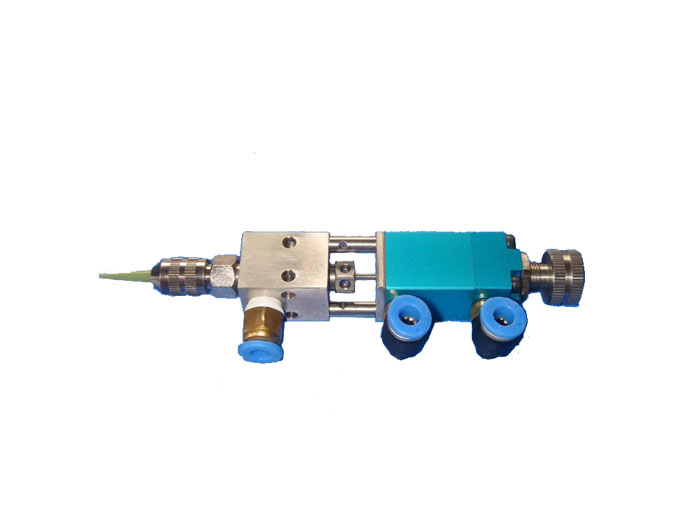

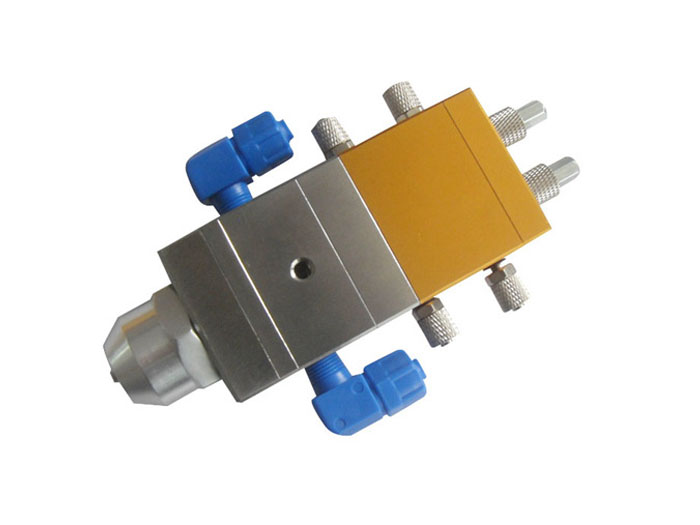

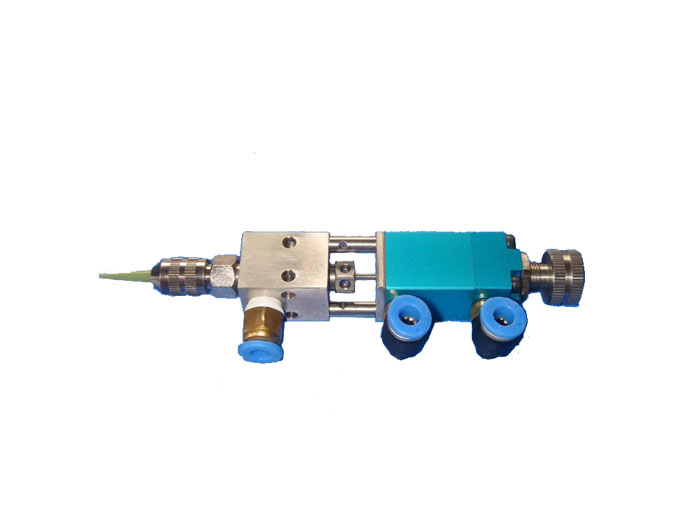

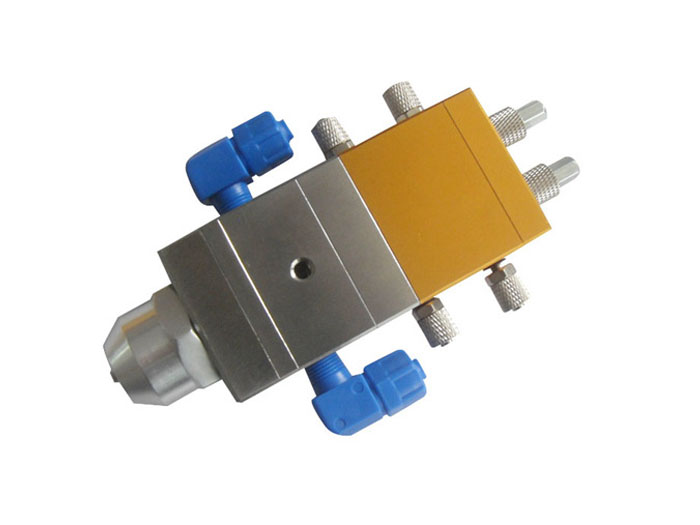

In the dispensing valve closure may be rubber valve leakage problems, mainly because the glue needle type is too small, the glue needle is too small to influence the flow of the liquid lead to back pressure, so there will be the problem of leakage occurs, and the glue needle is too small may affect the discharging water bubble effect, so choose the best choice of dispensing needle rules type large needles. Sometimes glue valve leakage is because the internal air exhaust is not clean and appear, preferably in the implementation of dispensing work before the glue and dispensing machine all the bubbles discharged, can solve the problem of glue valve dripping.

At present, the taper inclined dispensing needle is stable in many dispensing needles, and the backpressure is low when it is working, so that the dispensing work can be carried out stably and smoothly. Rubber valve drip may also be because the causes of poor sealing, consumer choice should pay attention to the quality of dispensing valve, there are some reasons for the rubber valve drip is mainly caused by the high corrosion resistance of glue, select the dispensing valve corrosion resistance can reduce the impact of glue to bring automatic dispensing valve.

The working pressure of the automatic dispensing machine is best established in the debugging stage, the glue valve drips sometimes because of the high pressure, so it is best to ensure the proper stability of the working pressure.