Function of automatic glue filling machine with glue meterin

作者:涂膠機(jī)???日期:2020-03-25 14:14???瀏覽:

Polyurethane glue filling needs to mix the glue and curing agent in the proportion of 5:1 to fully achieve the effect of polyurethane solvent, otherwise, it cannot be fully cured, which will lead to concave or convex points inside or outside, product defects and problems in use. How to complete the 5:1 glue proportion transportation? Need the help of glue metering pump of automatic glue filling machine to measure the glue output of glue a and glue B.

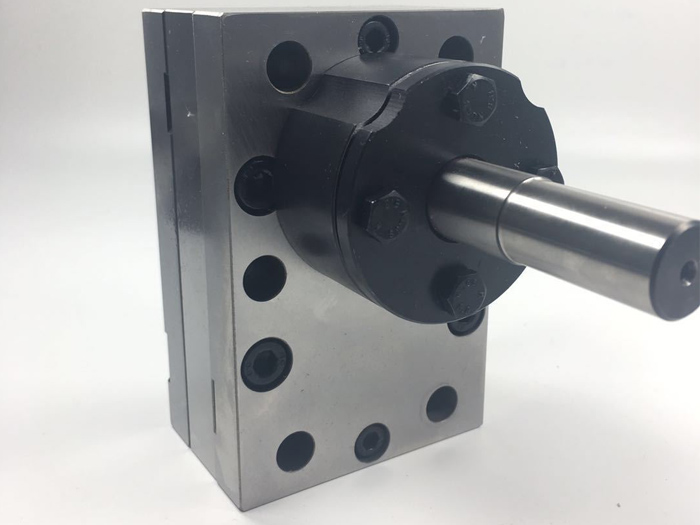

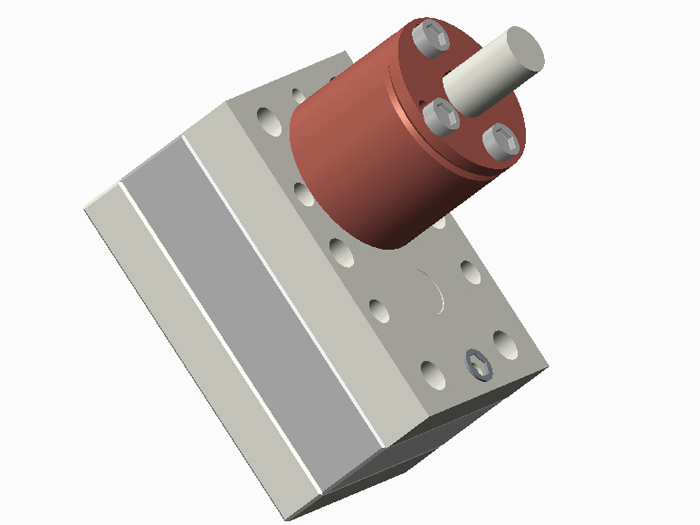

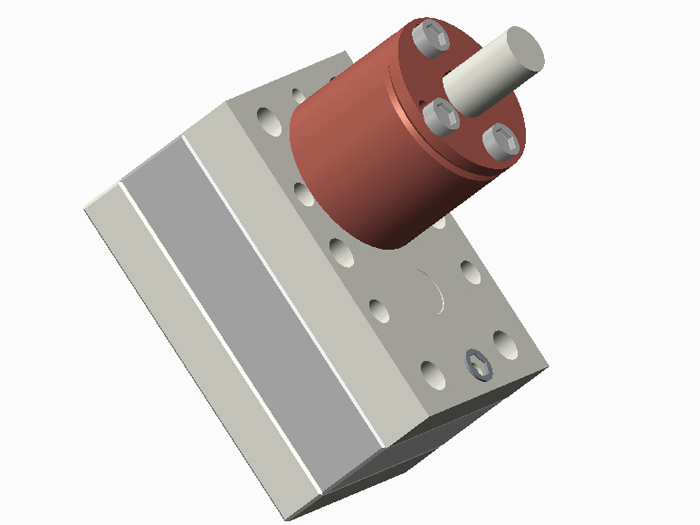

Working principle of glue metering pump: install the glue outlet of the automatic heating pressure barrel, measure the glue output of each pressure barrel according to the set glue output ratio, pump it to the conveying pipe together, and then deliver it to the glue point valve, mix it with the double liquid glue point valve, and fill the glue of the communication products.

Whether the automatic glue filling machine meets the requirements of polyurethane glue filling? The glue metering pump plays a very important role. Otherwise, the double liquid dispensing valve alone can not meet the requirements of polyurethane high proportion glue filling. Each machine requiring high proportion mixing needs to be equipped with a glue metering device, so as to solve the relative effect of glue quantity proportion. Now we understand that the metering pump is very important for the automatic glue filling machine Is it working?

At present, the glue mixing ratio that can only be made by double liquid dispensing valve is about 3:1 and below. Unless screw dispensing valve is used, glue with 10:1 and below can be used. However, one valve needs 80000 speed, which is higher than the price of one set of glue metering pump. However, the performance of screw dispensing valve lies in precision control, with high precision dispensing effect and high viscosity glue mixing effect If your company has cost, screw dispensing valve can be used for glue filling of communication products, and the quality of glue filling will be unexpected.

The automatic glue filling machine will make changes according to the use industry. Some of them will use glue metering pump and screw dispensing valve. For example, for the glue filling of communication products, some products need to be heated. The stainless steel pressure barrel will be equipped with a barrel heating device to ensure that the glue can meet the use requirements. The automatic heating pressure barrel is equipped with heating resistance to ensure that the glue can be quickly used Quick heating.

Automatic heating pressure barrel and glue metering pump are unique dispensing accessories, which can only be installed when required. At present, there are many industries that need automatic heating pressure barrel, because glue heating can improve the fluidity and viscosity of glue. After heating, it can improve the fluidity and production efficiency. The cost of installing a barrel heating device is not high, and the cost performance ratio is relatively cost-effective.