Dongguan Chang'an electric toothbrush sealing dispenser

作者:點(diǎn)膠機(jī)???日期:2020-07-04 14:19???瀏覽:

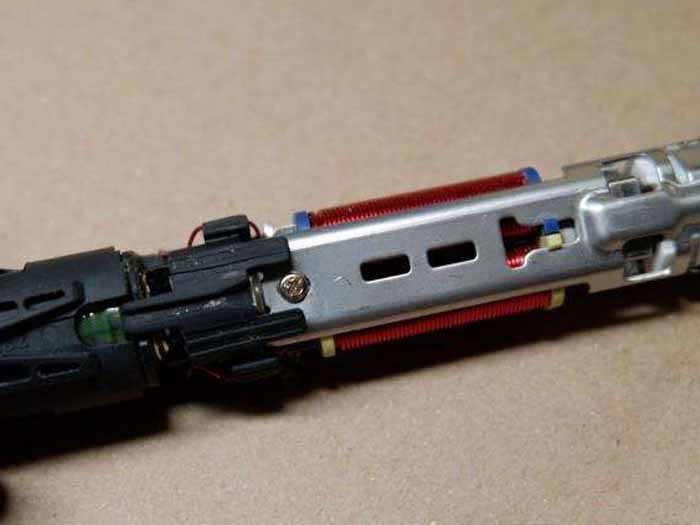

The sealing of electric toothbrush depends on manual operation. If there is no basic sealing technology demand, good sealing effect can not be achieved. Why is the price difference of electric toothbrush mainly due to the difference of technology and accessories? Every penny is worth of goods, and there is no fake. The cheap service life and accessories are certainly simple. After all, manufacturers will not make a loss, and the sealing of electric toothbrush is one of them Process.

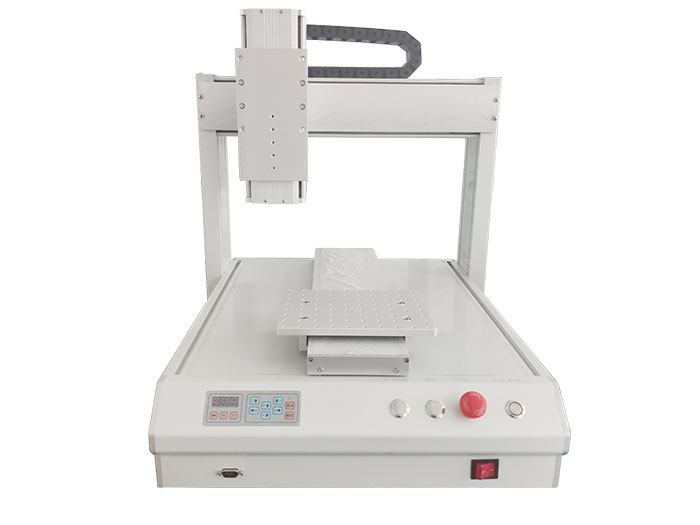

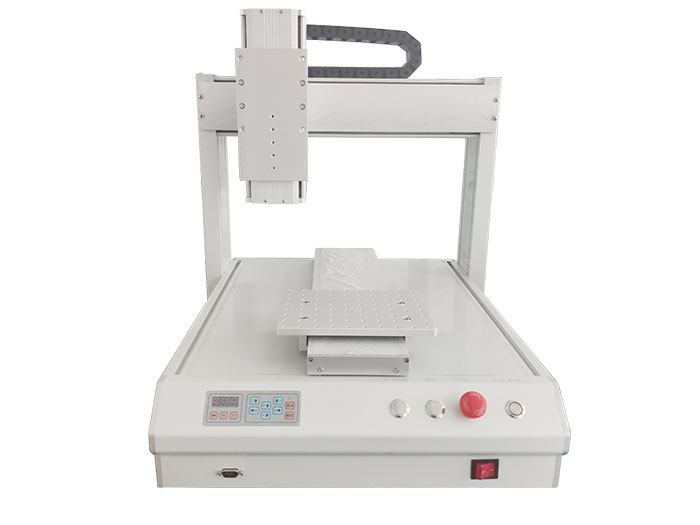

Our company is located in Dongguan Chang'an, we have our own dispenser manufacturer, we can do proofing video in our company! In order to meet the needs of manufacturers, they often make dispensing videos to manufacturers, and then send samples back to the manufacturers. The videos can see the speed and the samples can see the quality. Finding a professional manufacturer can solve a lot of dispensing problems. Our Changan dispensing machine is recommended for electric toothbrush dispensing. It can not only manufacture epoxy resin dispensing machine, but also make screw machine, which can meet the core requirements of electric toothbrush for screwing and dispensing.

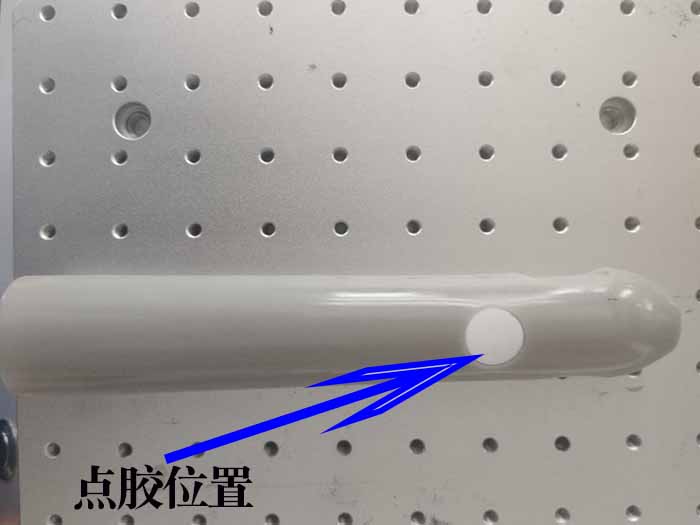

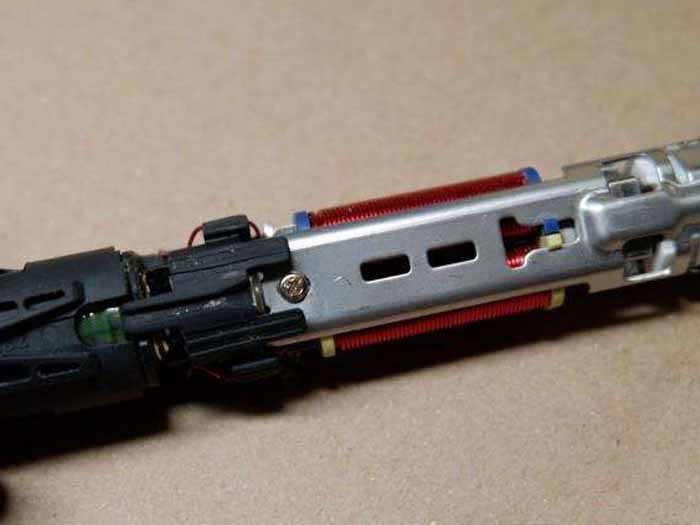

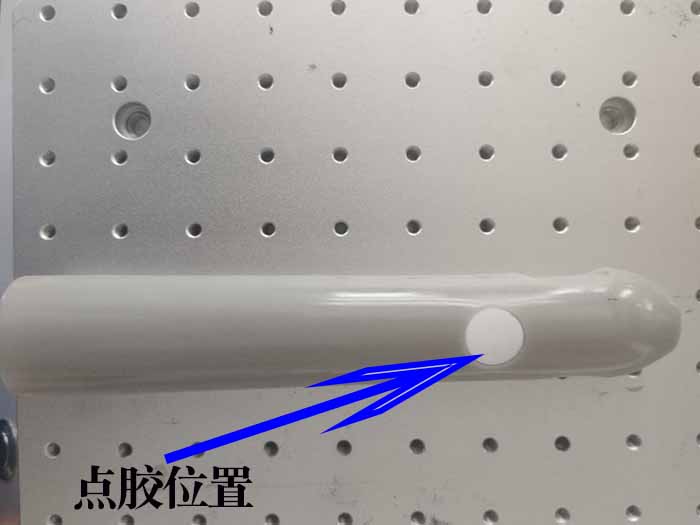

The glue used for sealing electric toothbrush is one-component epoxy resin adhesive, which has good sealing performance and can play the role of waterproof and bonding. It mainly applies glue on the key, which can have good bonding effect. The key is firmly bonded to the electric toothbrush to avoid the problem of water entering into the gap between the button and the electric toothbrush. Our machine can realize round dispensing and application effect The result is still good, our Changan dispensing machine manufacturer's machines, a wide range of applications, in the magnetic core bonding is also the use of this epoxy resin dispensing machine.

The electric toothbrush uses the desktop type automatic screw locking machine for screwing. The control system and dispensing device are replaced with a special screw locking system and an electric screwdriver, and a screw feeder is installed, which can automatically sequence the screws. This is the advantage of the manufacturer. According to the core requirements of the manufacturer, the production machine and mode can be changed to meet the needs of your company Glue, screw and so on, solve the problem of slow speed.