Automatic glue coating scheme for the bottom plate of electr

作者:涂膠機???日期:2020-05-08 20:20???瀏覽:

The electric iron belongs to one of the household appliances, also known as the electric iron, which is specially used for ironing clothes. In the production process, there is a gluing process. The single component room temperature curing silica gel is used as the sealing glue, which can be glued and bonded, and a layer of glue is applied at the bottom, which can play a good bonding role. The machine produced by our company can directly meet the requirements of gluing at the bottom of the electric iron, and can also be connected Lock screw technology.

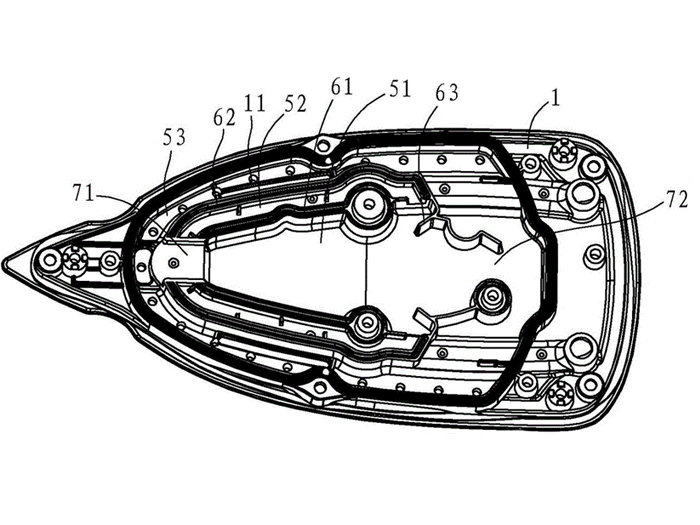

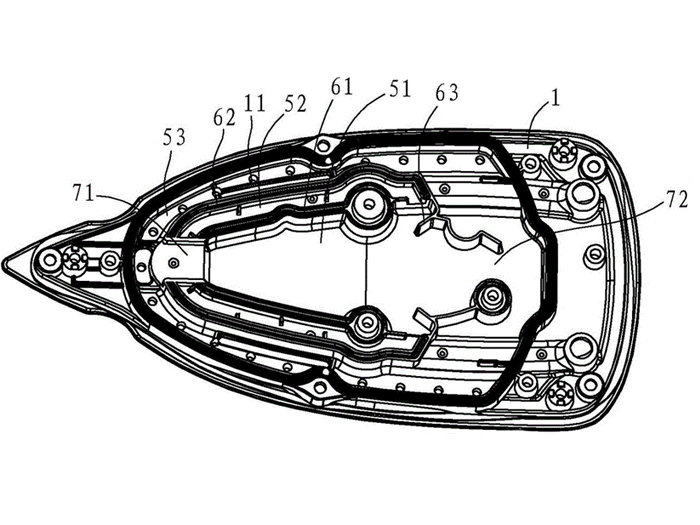

Mature coating technology of electric iron

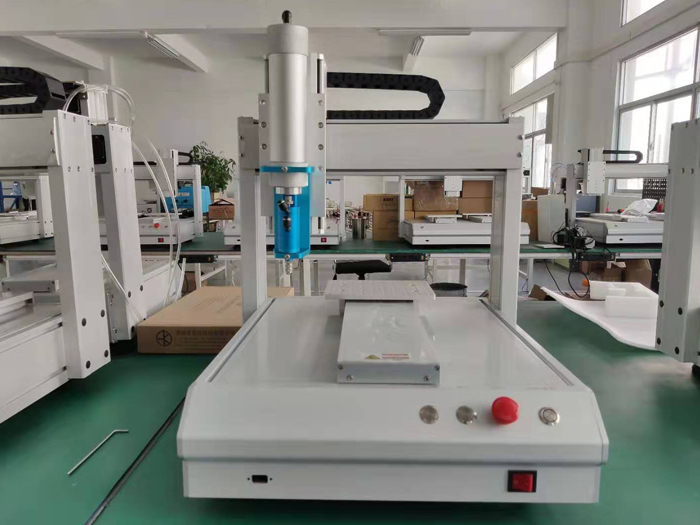

Our technology is very mature. According to the core requirements of the product, the three-axis automatic glue applicator is equipped with a large flow silica gel dispensing valve, which can control the silica gel with thick viscosity, as well as the suction effect, to avoid the problem of glue drawing. According to our production experience, the arc curve method is adopted, which requires high precision for the moving shaft. We use step motor to control the dispensing effect The accuracy can reach 0.1mm, the machine is cheap, the operation is simple, and the glue quantity control is stable.

Our machines are required to meet the requirements for the coating of electric iron. Our company has already had actual production cases in this respect. There are special machines. For the coating requirements of electric iron, if you choose our company, the price and quality are guaranteed. Silica gel is our mature use technology. If you want to avoid production problems, there must be no mistake in using our full-automatic coating machine. There are special ones The core technology of our company is that every product will have actual production cases before it can be produced, all of which are stored in Qingxi dispensing machine factory. There are many strongholds in Guangdong, such as Tangxia, Wanjiang and Hengli. At present, there are many places in Dongguan that have our machines.

Using any kind of core technology takes time to settle. Our company has no production experience in this field. From order to production, it only takes three days. This is a technology that can be achieved by mature manufacturers. There is no material inventory and no dispensing parts. How can it be made? A full-automatic glue applicator has about 50 parts. It only takes three days from material cutting to finished product, with the same speed When it's fast, we need to make samples, debug and send machines, which can be delivered to the surrounding cities.

Characteristics of solidified silica gel

Single component room temperature curing silica gel is commonly used. If your company has such needs, you can find our company's manufacturer. The glue coating technology at the bottom of the electric iron can be assured, which can solve the problem of your company's production. The single component greenhouse curing silica gel is suitable for the glue coating requirements. Our company also has an electric iron screwing machine, which actively configures the screws according to the screw requirements Wire feeder, suitable for screw demand. Our company has the technology to solve gluing and screw locking machine.

Qingxi dispenser manufacturer chooses our company's medium-sized system, with mature technology, fast production speed, guaranteed quality, door-to-door service, one-year quality assurance, lifelong paid maintenance. In the dispensing industry, we have more than ten years of production experience, which can meet your company's requirements for various dispensing, and gradually involves in the aspects of screwing and soldering. Qingxi dispenser manufacturer, I am.