LED energy saving light dispensing machine Dongguan Tangxia

作者:馬交易???日期:2019-12-21 09:24???瀏覽:

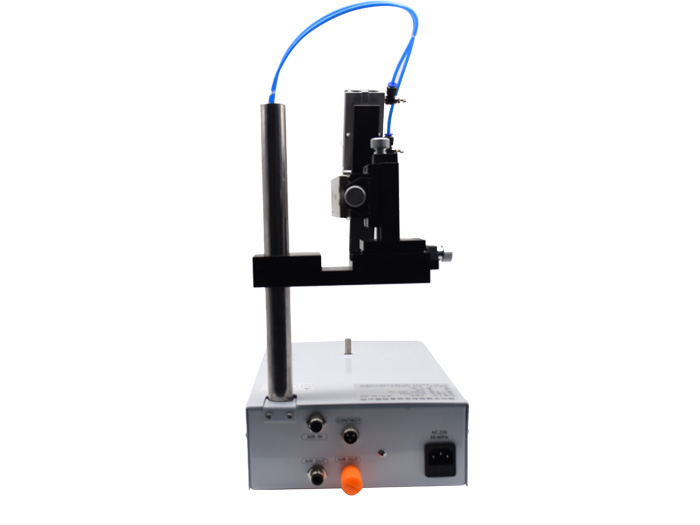

For the research and development of LED light tube dispensing equipment, our Chinese made automation equipment manufacturers belong to the early batch of manufacturers, with desktop type three-axis led dispensing machine, hard light strip filling machine and bulb lamp dispensing machine. The manufacturer is located at No.1, 6th Street, 128 Industrial Zone, Tangxia Town, Dongguan City, and is a Tangxia dispensing machine manufacturer. If the manufacturer of LED energy-saving lamp dispensing needs, it is more advantageous to investigate the strength of the manufacturer on the spot Shop in the factory!

The single component glue is generally used for the dispensing of LED energy-saving lamp, while the circular dispensing technology is required for dispensing in the lamp holder. A layer of glue is applied at the inner ball edge to seal and fix the inner parts, so as to avoid falling and have the effect of heat insulation. It is good for LED energy-saving lamp and prolong the service life of lamp bulb.

Production process: pour the glue into the pressure barrel, connect the air pressure, input the glue from the pressure barrel to the dispensing valve of the ball bubble dispenser, then design the dispensing path and the dispensing amount, start the machine, and automatically complete the dispensing of the LED energy-saving lamp.

The glue flow control is related to the input air pressure, the dispensing needle and the movement speed. The input air pressure determines the glue flow speed, the dispensing needle determines the size of the glue point, and the movement speed determines the amount of glue in the past path. These three points have a direct impact on the glue flow. To control the amount of glue, we must start from these three points. In fact, it is very simple to understand that the glue flow control is from the coarse and medium , fine, just from these three points.

The single component glue is easy to use. The glue viscosity and characteristics, such as whether the viscosity is thick or thin, match the corresponding dispensing valve, and directly assemble on the machine. In fact, these are all handled by the dispenser manufacturer. As long as you send the sample and glue to the manufacturer together, explain the dispensing requirements, dispensing speed, glue output and production speed requirements, the manufacturer can tell the dispenser manufacturer according to the requirements Make proofing video for you as required. If you have video, you can know whether you can do it and how it works. You don't need to talk about it on paper.