Causes of leakage of plunger dispensing valve

作者:馬交易???日期:2019-11-28 17:37???瀏覽:

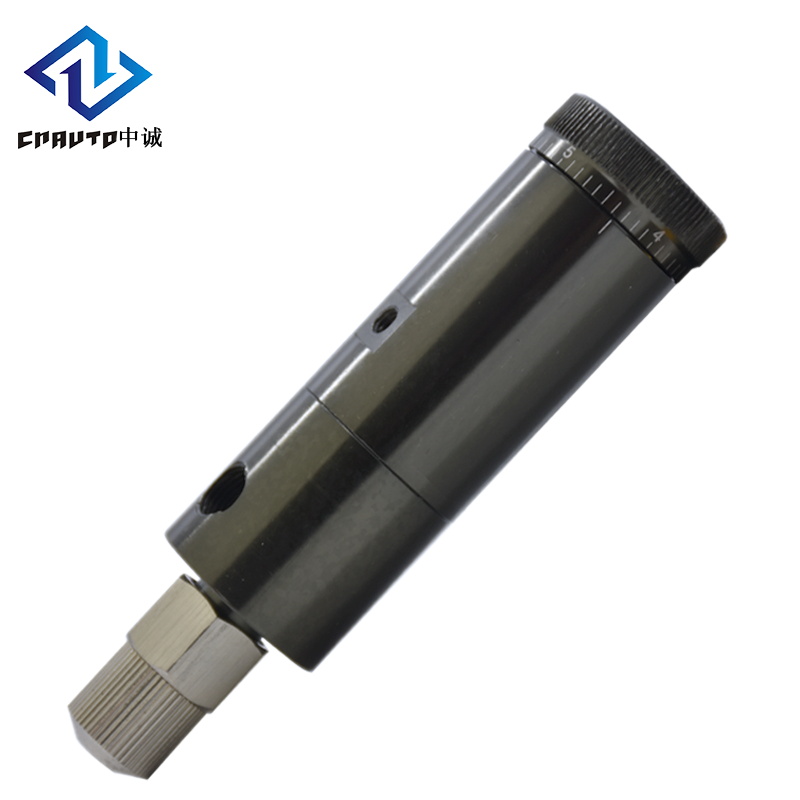

As the dispensing valve has been used for a long time, there will be leakage of glue. Take the leakage of plunger dispensing valve as an example to explain the main problem of leakage of starting point glue valve. Plunger dispensing valve is "famous" for its ability to use high viscosity glue and good sealing performance. It is a representative dispensing valve.

Glue leakage caused by the back suction function of glue valve

The plunger type dispensing valve used in the tabletop dispensing machine has the function of suction back. The suction back can prevent the wiredrawing problem after dispensing, and there will be disadvantages. When it is used with a smaller needle, it will form a suction back vacuum, so that the rubber valve can not have the effect of suction back, nor can it play the role of sealing, so that the glue flows out of the plunger type dispensing valve, which is the problem of suction back and leakage.

The glue has bubbles

It is a very common thing that there are bubbles in the glue. When we use the tabletop dispenser for dispensing, the improper operation will cause the gas to enter into the glue from the plunger dispensing valve. The formation of bubbles will reduce the suction force of the glue valve and directly lead to the leakage of the plunger dispensing valve, which are the two main reasons.

Solution

In fact, it is very simple to solve the problem of glue leakage of the plunger type dispensing valve. As long as the replacement of the needle is bigger than the original one, it can solve the problem of glue leakage of the plunger type dispensing valve. The solution is simple. In fact, it is the same to solve the problem of air leakage of the plunger type dispensing valve, or the dispensing parts are not tightened. Secondly, the dispensing valve can be used to exhaust the air, so that there is no bubble in the glue, so the plunger type dispensing can be solved For the problem of valve air leakage, it is required that the glue will not automatically generate bubbles. Like the epoxy resin glue, the vacuum defoaming method should be used.

The most common problems of using plunger type dispensing valve in desktop dispensing machine are glue leakage and air leakage. Both of the two problems are that there is no matching of proper dispensing accessories, and the back pressure is easy to form when the needle is too small (the back pressure will be equal to the back suction pressure of dispensing valve, and the glue will fall naturally, resulting in glue leakage). As long as the needle is replaced, the problem of glue leakage can be solved, and it is needed every 15 days Replace the sealing ring once, because the glue is corrosive, it will corrode the sealing ring, resulting in air leakage of plunger type dispensing valve.