SZ CnAuto automation equipment Co., Ltd.

Specializing in the production of automatic\precision\high speed dispenser manufacturers

Hot Tel:

18929475867

Specializing in the production of automatic\precision\high speed dispenser manufacturers

Hot Tel:

18929475867

TEL:

18929475867

深圳中制自動化設(shè)備有限公司

Email:jerry@prcrobot.net

QQ:a :

ADD:東莞市塘廈鎮(zhèn)石潭浦大逕路62號

作者:馬交易???日期:2019-11-06 15:09???瀏覽:

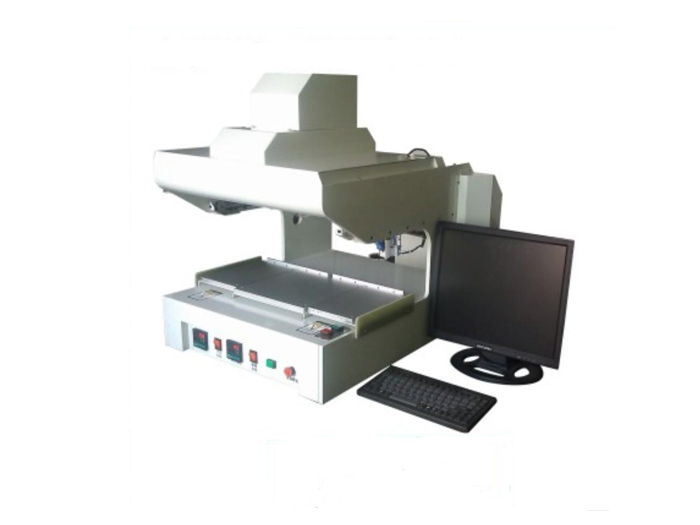

It can strengthen the durability of the sole, and greatly increase the impact resistance of the material for making the insole after the overall molding. Generally, a large number of insole manufacturers use this material when they are dispensing the insole, that is, PVC. There are two ways to dispensing the insole on the production line: Manual dispensing, conventional dispensing machine dispensing, and visual dispensing machine recommended by small knitting Compared with the raw materials used manually, the visual dispensing machine will reduce the amount of raw materials, which can give full play to the characteristics of glue. That's what the insole dispensing needs. The machine will dispensing after testing the place where dispensing is needed. When the two sides that need to be glued together stick together, they will become very solid, so it is more recommended to use the visual dispensing scheme for the insole Feel dispenser.

It can strengthen the durability of the sole, and greatly increase the impact resistance of the material for making the insole after the overall molding. Generally, a large number of insole manufacturers use this material when they are dispensing the insole, that is, PVC. There are two ways to dispensing the insole on the production line: Manual dispensing, conventional dispensing machine dispensing, and visual dispensing machine recommended by small knitting Compared with the raw materials used manually, the visual dispensing machine will reduce the amount of raw materials, which can give full play to the characteristics of glue. That's what the insole dispensing needs. The machine will dispensing after testing the place where dispensing is needed. When the two sides that need to be glued together stick together, they will become very solid, so it is more recommended to use the visual dispensing scheme for the insole Feel dispenser. The main reason for the recommendation of using visual dispensing machine is its accurate visual positioning system, which can effectively and stably locate the areas requiring dispensing.

The main reason for the recommendation of using visual dispensing machine is its accurate visual positioning system, which can effectively and stably locate the areas requiring dispensing.