Do you know what dispensing equipment should be debugged?

作者:自動(dòng)點(diǎn)膠機(jī)???日期:2019-10-17 06:19???瀏覽:

Many customers often ask about the debugging of automatic dispensing equipment. In fact, debugging is not difficult. However, it is not easy to master the professional level. Generally, professional technicians are needed to guide the debugging and service of dispensing equipment to ensure that users use dispensing machine correctly and meet the dispensing requirements.

1. Pressure setting in automatic dispensing equipment

Pressure setting of dispensing equipment is relatively stable. Under normal circumstances, dispensing control quantity is provided to rubber hose and needle by controller. The dispensing pressure determines the dispensing quantity and speed. The dispensing pressure when dispensing automatically is too large or too small will affect the quality of product dispensing. Precision control of dispensing is very important.

2. Setting up of glue output of automatic dispensing equipment

The dispensing quantity should be set to 1/2 of the product spacing to ensure that there is enough dispensing quantity to stick the components and prevent excessive glue leakage. The dispensing time of automatic equipment can be adjusted by dispensing. Specific adjustment requirements according to different products and process operation dispensing equipment debugging allocation and allocation time.

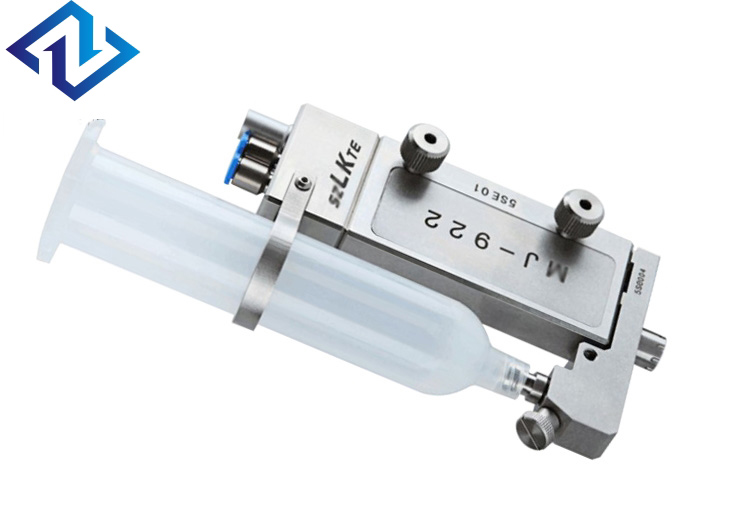

3. Selection of dispensing needle

The dispensing needle is an indispensable accessory in the process of contacting dispensing. It is suggested that the diameter of the dispensing needle should be 1/2 of the diameter of the dispensing point, which is more conducive to the debugging of dispensing equipment. In the dispensing work, all dispensing configurations should be selected according to the characteristics of the product. Choosing the appropriate dispensing needle according to the size of the product can also follow the manual suggestion of dispensing technology.