Glue types and precautions for screen bonding of mobile phon

作者:馬交易???日期:2019-08-27 18:07???瀏覽:

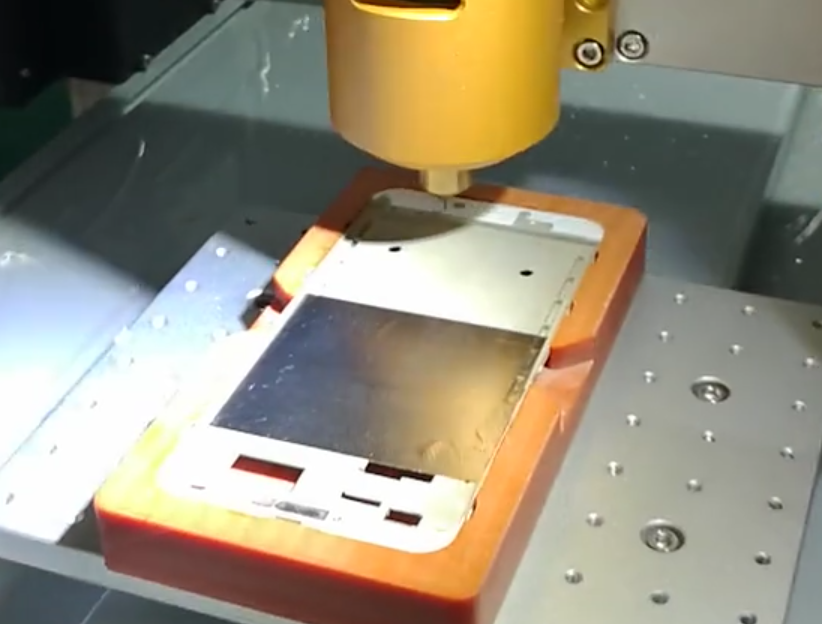

Hot melt dispenser is mainly used for sealing and bonding of electronic products such as mobile phones, notebooks and mobile phone shells. It is not only waterproof and sealed, but also dustproof, shockproof, adhesive and insulation. Hot melt adhesive is a common type of glue for electronic protection and assembly. It is also a PUR electronic adhesive. It is often used to bond the screen of notebook and mobile phone.

Background:

Modern electronic products are becoming more and more intelligent, light, light, easy to carry and easy to use. For example, the screen of mobile phone is thinner and lighter, the required dispensing accuracy is more accurate, the corresponding dispensing gap is naturally finer, and the requirements for hot melt adhesive machine will be higher.

The function of PUR hot melt adhesive:

1. Bonding:

Polyurethane hot melt adhesives can be applied to the screen bonding of mobile phones, which can be coated into 0.2mm thin wires, and ensure sufficient bonding strength. After bonding, it can also play an anti-shock role. After bonding, the hot melt adhesives also have flexibility to ensure that the internal core parts remain unchanged, and only after closing these voids, the outside of mobile phones. Watching will be wet by rain, which will greatly reduce the possibility of infiltration into the inside of the mobile phone, and enhance the practical application of the mobile phone.

2. Insulation:

Polyurethane hot melt adhesive has good insulation performance and can effectively reduce leakage and electric shock caused by damp air or other reasons.

Advantages of PUR hot melt adhesives:

1. Good weather resistance, irreversible characteristics after curing, will not occur due to changes in ambient temperature, will always maintain the state after dispensing.

2. It has high toughness, strong initial adhesion, strong permeability and affinity.

3. Under the same conditions, the bonding strength is 40-60% higher than other adhesives, which reduces the use of adhesives.

4. It has good impact resistance and good adhesion of various substrates.

Polyurethane hot melt adhesive is a kind of wet curing active polyurethane hot melt adhesive, which has excellent bonding strength and impact resistance, excellent bonding strength, temperature resistance, chemical corrosion resistance and aging resistance. It is one of the most important types of adhesives in the adhesive industry. In practice, customers sometimes encounter the situation that hot melt adhesive can not be properly removed. You can consult the hot melt Jao dispenser, which can help you to solve the problems of screen bonding.

If the glue cannot be discharged smoothly at room temperature (between 115 C and 130 C) and atmospheric pressure (less than 6 bar), please check carefully whether:

1. Plastic needle nozzles melt due to high temperature. At this point, you must stop immediately, you must use stainless steel dispensing needle, in order to withstand high temperature. Do not force the use of plastic dispensing needles or air pressure to avoid accidents.

2. Next day, the glue is dispensed again, which causes the glue at the needle mouth to solidify. At this point, the hot melt adhesive needs to be heated again and the new needle opening needs to be replaced. Avoid unsafe problems caused by excessive internal pressure

3. If after heating, the hot melt adhesive still retains particles, the temperature has reached the melting point of the hot melt adhesive, at this time, need not reheat the glue, wait for the glue to cool down, if the glue can not be selected, we must replace the new glue, can not forcibly adjust the temperature or pressure, so as to avoid the mobile phone screen bonding process. Now the glue is blocked.

Modern electronic products are becoming more and more intelligent, light, light, easy to carry and easy to use. For example, the screen of mobile phone is thinner and lighter, the required dispensing accuracy is more accurate, the corresponding dispensing gap is naturally finer, and the requirements for hot melt adhesive machine will be higher.

Modern electronic products are becoming more and more intelligent, light, light, easy to carry and easy to use. For example, the screen of mobile phone is thinner and lighter, the required dispensing accuracy is more accurate, the corresponding dispensing gap is naturally finer, and the requirements for hot melt adhesive machine will be higher. 1. Bonding:

1. Bonding: