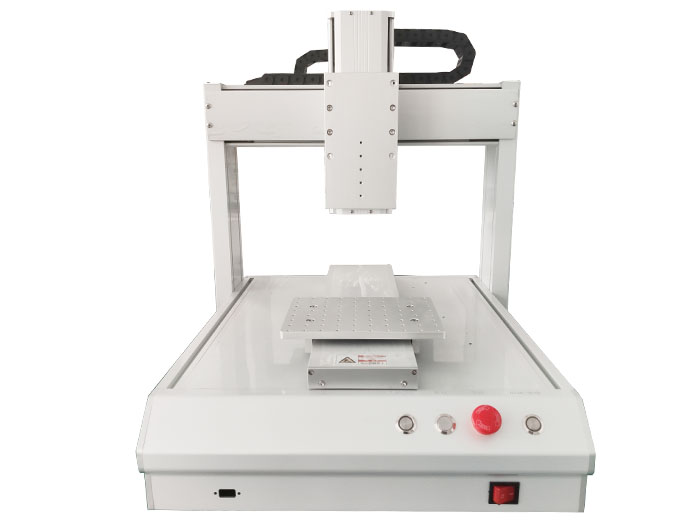

SZ CnAuto automation equipment Co., Ltd.

Specializing in the production of automatic\precision\high speed dispenser manufacturers

Hot Tel:

18929475867

Specializing in the production of automatic\precision\high speed dispenser manufacturers

Hot Tel:

18929475867

TEL:

18929475867

深圳中制自動化設(shè)備有限公司

Email:jerry@prcrobot.net

QQ:a :

ADD:東莞市塘廈鎮(zhèn)石潭浦大逕路62號

作者:馬交易???日期:2019-08-12 22:43???瀏覽:

The automatic dispensing machine provides a certain pressure for the needle or rubber gun to ensure the supply of glue. The pressure determines the amount and speed of glue. If the pressure is too high, the glue will overflow and the amount of glue will be too much. If the pressure is too low, there will be intermittent and leak point problems affecting the glue control, which will lead to product defects. Pressure should be selected according to the nature of glue and the temperature of the working environment. The ambient temperature will make the glue viscosity smaller and its fluidity better. At this time, the pressure value should be reduced, and vice versa.

The automatic dispensing machine provides a certain pressure for the needle or rubber gun to ensure the supply of glue. The pressure determines the amount and speed of glue. If the pressure is too high, the glue will overflow and the amount of glue will be too much. If the pressure is too low, there will be intermittent and leak point problems affecting the glue control, which will lead to product defects. Pressure should be selected according to the nature of glue and the temperature of the working environment. The ambient temperature will make the glue viscosity smaller and its fluidity better. At this time, the pressure value should be reduced, and vice versa.