How to choose the jet valve of automatic dispensing machine?

作者:馬交易???日期:2017-11-17 11:29???瀏覽:

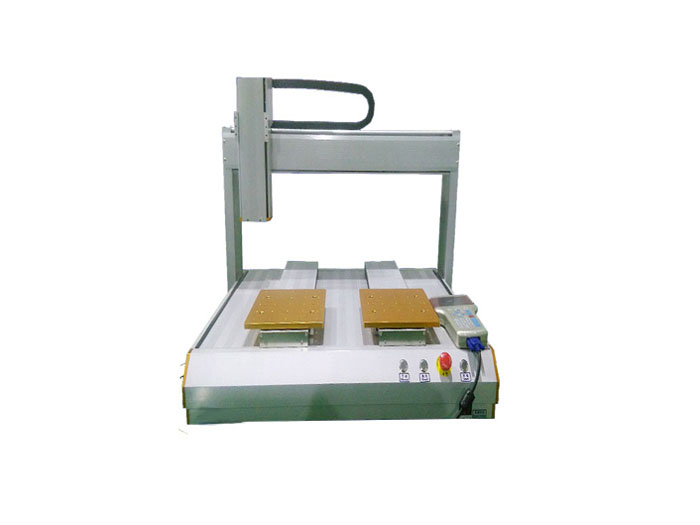

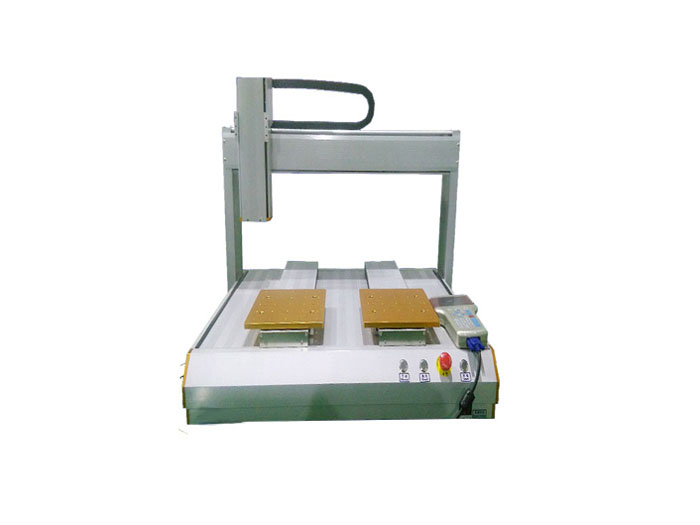

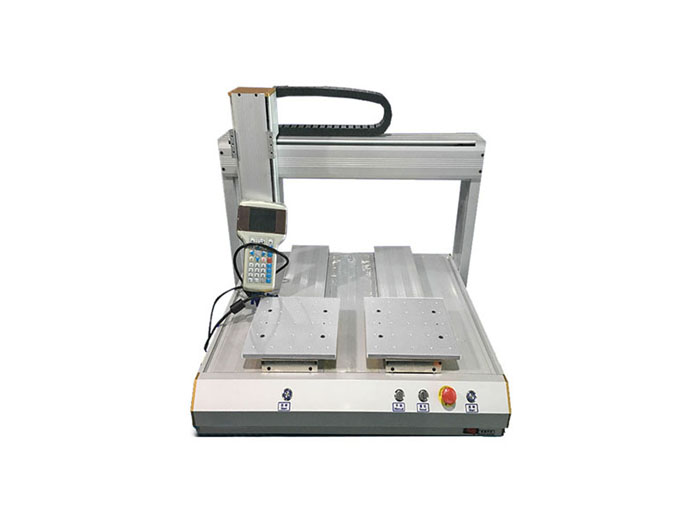

Automatic dispensing machine in the manufacturing industry plays a very important role, through the dispensing work automatic control system can help users of various demands, the function of automatic dispensing valve dispensing work supports the use of different, of course, is the injection valve automatic dispensing function configuration, if the user needs to perform non-contact dispensing need to select the appropriate injection valve.

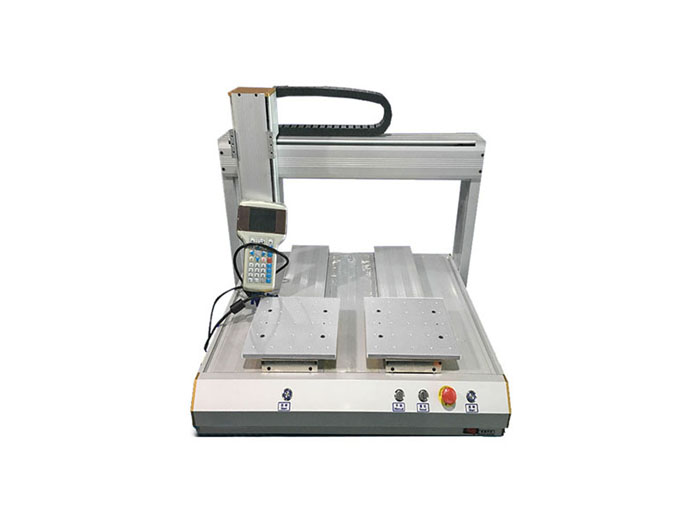

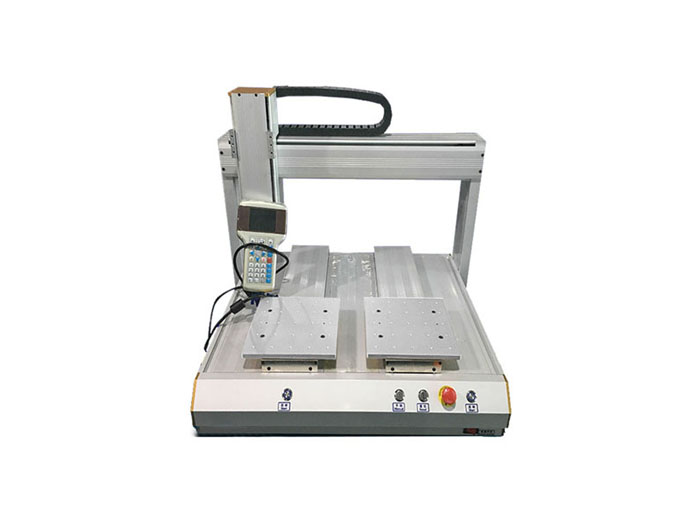

Injection valve is one of the most important parts to realize the non-contact dispensing, jet automatic dispensing machine is the use of this valve, the injection valve can achieve high precision dispensing work, through processing the fluid to spray mist to glue coating, not only a wide area and intensity of the dispensing butt is not affected, without implementation of Z axis can greatly reduce the demand for dispensing time, some of the high demand of the production line have adopted the way of glue dispensing work, if need to perform automatic dispensing glue need reasonable selection of injection valve.

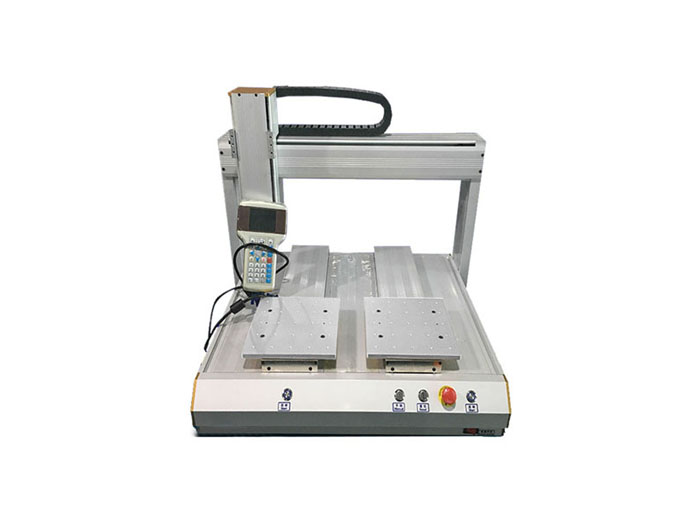

As the jet valve is the implementation of high-pressure dispensing work, so the jet valve is best made of high hardness material, and can handle different viscosity of glue, to ensure high precision glue out work. A piezoelectric type injection valve for example, piezoelectric ceramic piece injection valve is based on the principle of bending deformation of rubber to perform work, by controlling the voltage to the steady state of the spray injection valve that can make the dispensing quality has been further improved, the use of the dispensing valve only can work to ensure the voltage stability, power consumption the lower is the dispensing valve a practical high.

Although the piezoelectric jet valve has higher working strength, it is necessary to confirm whether the dispenser can match the user before choosing the dispensing valve.