Water proof glue filling for power supply

作者:點膠機???日期:2020-07-24 21:47???瀏覽:

Silicone sealant is generally used for power supply waterproofing, insulation and protection. It is very important for power supply glue pouring. However, what type of full-automatic glue pouring machine is used is the key. If you choose a product with advantages, it will be of great help to the production. Let's learn how to pour the power supply with the automatic glue pouring machine produced by our company What's the effect of glue?

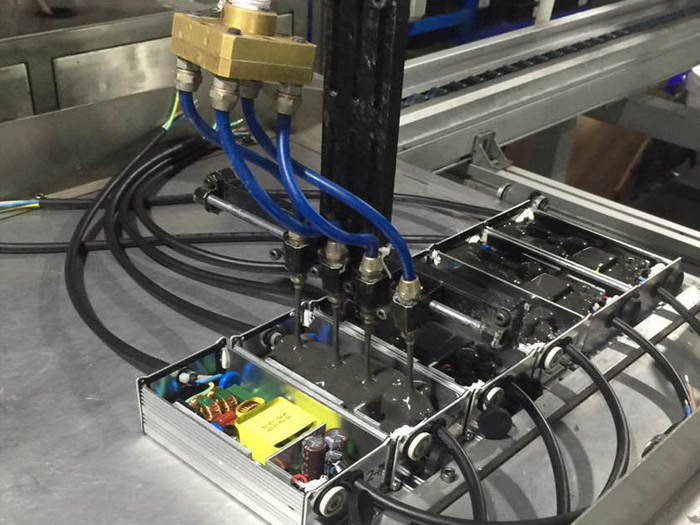

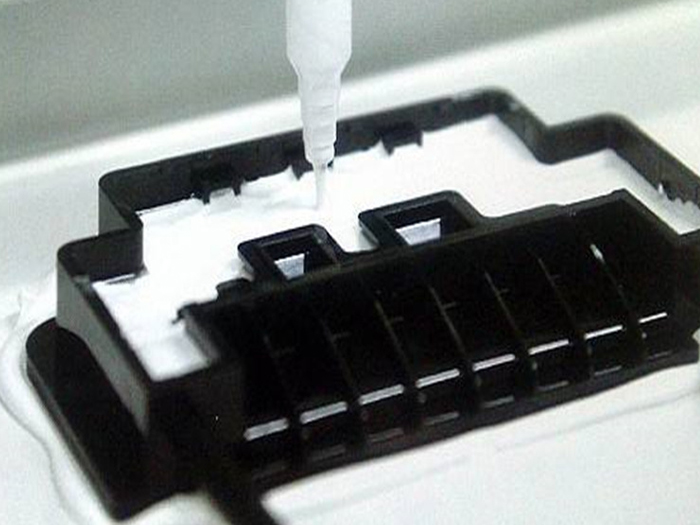

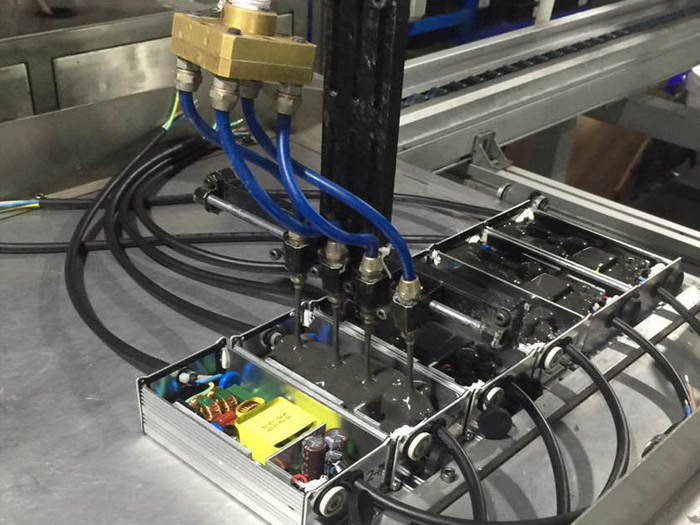

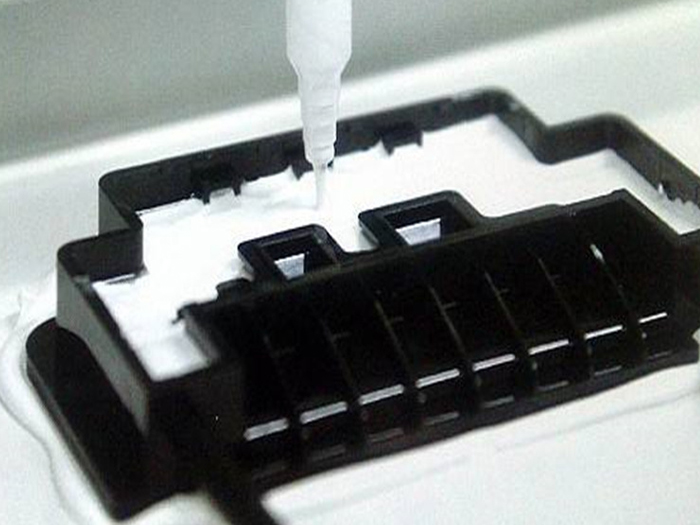

Floor type gluing machine is a non-standard machine. As an example in our company's application, this is a power supply device, which belongs to voltage device. It is applied in LED industry. The external aluminum alloy is wrapped in the internal device, only three are wrapped, and the fourth side needs to be filled and sealed, which requires a large amount. Our company configures four glue outlet heads on the floor type glue pouring machine to realize sustainable pouring Glue, quickly fill the whole power supply, this is our company's water-proof glue filling scheme, you can change the glue mode according to the specifications, the dispensing valve is customized from our company, you can change it at will.

The glue is extracted from the pressure barrel and transported to the double liquid dispensing valve through the metering pump of the floor type glue pouring machine. After mixing, the glue is divided into four parts and transported to the power supply respectively. Some customers ask why it is so troublesome because the single axis is not good at controlling the glue quantity and can not meet the specific requirements, so it can be separated into four axes, which has strong uniformity and can be better controlled, The glue filling speed is relatively fast, and the use is very simple.

Stainless steel dispensing valve is a two-component dispensing valve used by our company with power supply for water-proof glue filling. The glue ratio can reach 5:1, and there is also a mixing device. If the ratio exceeds this ratio, a better stainless steel dispensing valve should be used. Four rubber pipes are extended at the glue outlet, and a device will be installed at the glue outlet to fix the four pipes, so that they can be arranged horizontally and conveniently Dispensing, this is the main reason why we choose stainless steel dispensing valve. The modification effect is very good, the hardness is enough, the air pressure input is relatively large, and it is relatively convenient.

It is also a guarantee for the manufacturer to select the manufacturer for the processing of AB glue pouring machine. Both the production and after-sales support are in line with the requirements. The floor type pouring machine produced by our company is used for water-proof glue pouring. The glue viscosity, mixing ratio and glue flow rate do not need to be worried. Our company can meet the requirements. This is the guarantee that the AB glue pouring machine processing center can give Face to face demand, welcome to call the service hotline: 13662812001