Apply hot melt adhesive to realize automation! Let's have a

作者:馬交易???日期:2019-12-10 17:07???瀏覽:

Hot melt adhesive is different from general glue. Due to the high temperature of other glue, it will destroy the internal chemical bond and lose the property of glue. However, hot melt adhesive needs to reach about 130 degrees to melt, while some can reach about 170 degrees. If you want to use hot melt adhesive, you must heat it, or you can't dispensing.

At the beginning, the hot-melt adhesive strip was put into the hot-melt adhesive gun by pistol dispensing. The hot-melt adhesive strip was dispensed and melted at the same time. It was controlled by hand. However, the glue output was large and the precision was not good. After each dispensing, the new strip was plugged in and dispensing was carried out again. This is the old dispensing process, which may not meet the existing production demand. For example, the most traditional way is used for filling the display screen Type is not up to the technical requirements, but need to use the new automatic dispensing machine.

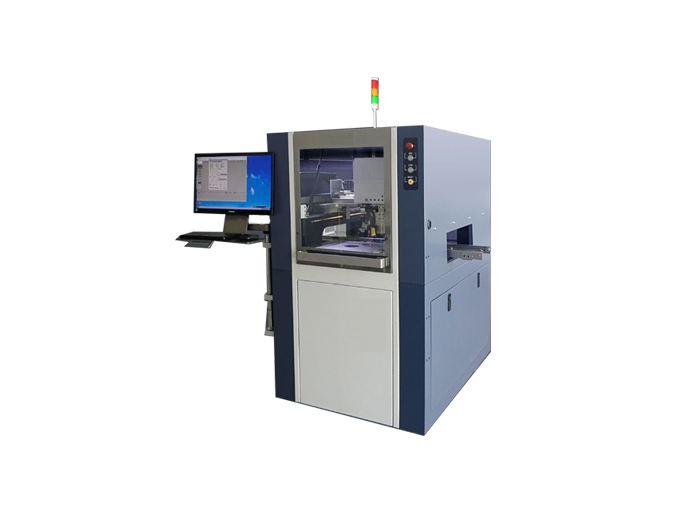

The automatic dispensing machine uses the original manual dispensing to today's automatic glue control, with better precision. The glue is no longer used in the traditional way of use, but can be stored on the hot melt glue dispensing valve, which can store 30ml at a time. For some small products dispensing, one morning is enough. The continuous dispensing effect is fast, and the hot melt glue coating effect is better than the traditional dispensing effect. Some requirements A large number of machines, but also other types of automatic dispensing machine.

In order to solve the existing production mode and meet the dispensing requirements of more products, it is no longer difficult to inject glue into the display screen. It can solve a variety of hot-melt adhesive problems and solve the existing dispensing problems. With the development of gelatinization technology, there are many ways of gelatinization, and the effect is better.