How to solve the leakage problem of plunger dispensing valve

作者:馬交易???日期:2019-11-28 17:35???瀏覽:

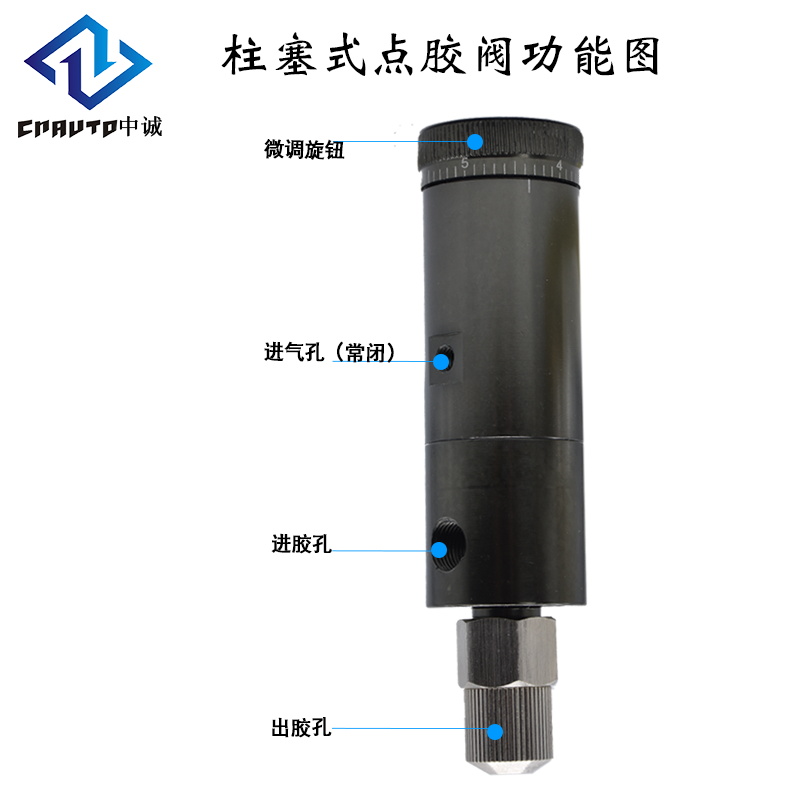

As a popular dispensing valve, plunger type dispensing valve has more and more users, among which there are also some problems, such as leakage and air leakage. How to solve these common problems of dispensing valve? We need to analyze the root cause to find a solution. Let's study the leakage of plunger dispensing valve.

The glue used in the tabletop dispenser will be corrosive to some extent, which may not be very corrosive for a long time. It will still corrode the inner sealing ring of the plunger type dispensing valve, which will cause air leakage and glue leakage. The inner sealing ring needs to be replaced regularly. The plunger type dispensing valve we produce is made of stainless steel and aluminum alloy. The aluminum alloy has good anodizing treatment Corrosive, the service life of rubber valve is longer, it is the service life of fittings is shorter, the sealing ring with strong corrosivity can only wait for one week, while the corrosivity is general, it can last for half a month.

To solve the leakage and leakage of plunger dispensing valve depends on the actual use. For example, the table top dispensing machine uses plunger dispensing valve to spot solder paste. The solder paste is neutral and has no corrosion function. The service life of sealing ring will be improved. In fact, the leakage and leakage are related to the viscosity of glue, operation process and parameter input. The solder paste is a high viscosity glue with poor liquidity, If a relatively small needle is used in the dispensing process, it is easy to form a vacuum between the plunger type dispensing valve and the needle, resulting in leakage after dispensing. The solution is to replace the larger needle. If the leakage is caused by other factors, it should be solved according to the actual situation.

Causes of air leakage of plunger dispensing valve

1. The tabletop dispenser input too much atmospheric pressure, the plunger type dispensing valve can not bear, resulting in air leakage.

2. There is an error in the programming of the machine system, and the air pressure control is not stable, resulting in the air leakage structure.

3. The sealing ring is very important in the plunger type dispensing valve, which can prevent glue leakage and air leakage.

4. For solder paste, a high viscosity glue, the configured needle should not be too small, or the plunger type dispensing valve will leak glue and air.

Although there are many problems causing leakage of plunger dispensing, there are many solutions. According to the above methods, you can solve the problem of leakage of plunger dispensing valve. The same is true for other types of dispensing valves. When we use desktop dispensing machine, we need to take into account that the use of glue matches the dispensing valve. Different glues may have more suitable dispensing accessories, tin dispensing The plunger type dispensing valve can be used for the paste, or 3131 dispensing valve can be used, but the former has better effect and cheaper price, so it should be more inclined to the plunger type dispensing valve.