Can spray dispenser use instant-drying dispenser?

作者:吳交易???日期:2019-08-08 22:15???瀏覽:

Instant drying dispensing machine is a special equipment specially used for distribution control of instant drying glue. Because the nature of glue will condense rapidly when it confronts with the atmosphere, the creep control function is added to the original dispenser base, and the precise control of distribution is stopped. The application task of the instant drying dispenser is to apply a special adhesive on the printed circuit board after the position of the patch is needed, so as to firmly paste the patch components and solidify them.

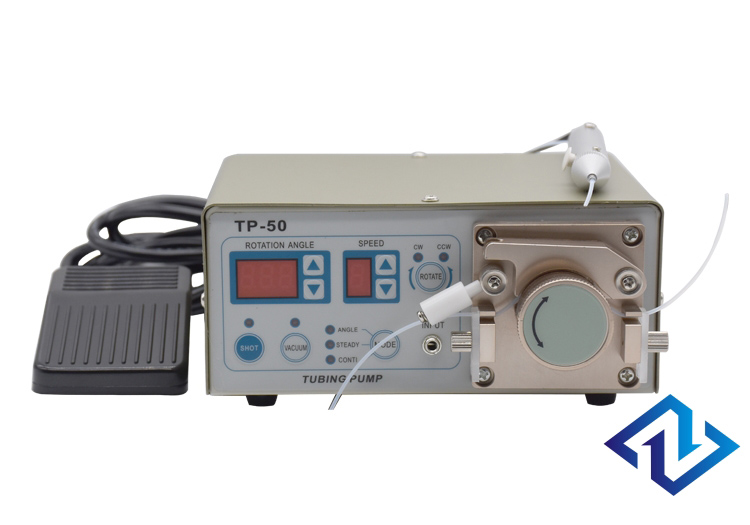

Then through wave soldering, dispensing will stop automatically according to the order. Instant drying dispensing machine is also called instant dispensing machine, while the outside industry is called peristaltic dispensing machine. This dispensing machine belongs to it.

Common dispensing products are specially designed for instant-drying gum and instant-drying gum. Practical liquid control series: UV glue, AB glue, dry glue, epoxy glue, sealant, quick-drying glue, 502 glue, etc.

The application of instant drying dispensing machine is different from that of ordinary pneumatic dispensing machine. The application of instant drying dispenser does not need pneumatic drive, as long as the power supply is turned on, the distribution products needed by customers can be quantitatively and timely distributed.

Result: No obstruction, curing glue, leaking glue and other problems, good accuracy, difficult operation. The following areas can be used with an adhesive distributor:

1. Electroacoustic industry: speakers, loudspeakers, buzzers, headphones

2. Inductance industry: small transformer, patch transformer, inductance, relay, small coil motor.

3. Communications industry: cell phone buttons, cell phone shell bonding, speakers, telephones, fax machines

4. Adhesion of computers, digital products, digital cameras, MP3, MP4, electronic toys and shells

5. Switches, Connectors, Wires, Plug Connections

6. Electronics: solder paste for electronic components, integrated circuits, circuit boards, solid electronic components, dust-proof and moisture-proof maintenance, liquid crystal display, etc.

7. Optics: optical lens, optical head and magnetic head

8. Mechanical Hardware

9. Battery Box Sealing

10. Brand Firm Combination

11. Task Principle 1 of the Light Emitting Diode Industry. Working Principle: The compressed air is fed into the rubber bottle (syringe), and the rubber is pressed into the feed pipe connected with the piston chamber. When the piston is in the upstream stroke, the piston chamber is filled

Fill with glue. When the piston pushes down the needle, the glue is squeezed out of the needle nozzle. The amount of glue dropping is determined by the interval between the piston insertions, which can be manually adjusted and controlled by software. 2. Features: High Speed

Fast speed, low sensitivity to adhesive viscosity. 3. Disadvantage: It can increase the dispensing rate, improve the dispensing situation and improve the quality of the dispensing.

Result: No obstruction, curing glue, leaking glue and other problems, good accuracy, difficult operation. The following areas can be used with an adhesive distributor:

Result: No obstruction, curing glue, leaking glue and other problems, good accuracy, difficult operation. The following areas can be used with an adhesive distributor: 6. Electronics: solder paste for electronic components, integrated circuits, circuit boards, solid electronic components, dust-proof and moisture-proof maintenance, liquid crystal display, etc.

6. Electronics: solder paste for electronic components, integrated circuits, circuit boards, solid electronic components, dust-proof and moisture-proof maintenance, liquid crystal display, etc.